The Process Aid Masterbatch

Introduction:

In the dynamic realm of polymer materials, innovations continue to shape the landscape, driving efficiency and performance. One such groundbreaking advancement is the Process Aid Masterbatch, a catalyst in polymer processing that has garnered attention for its transformative impact. This article delves into the intricacies of the Process Aid Masterbatch, emphasizing its significance, and highlighting Ehda Polymer Co as a leading producer in this realm.

Understanding Process Aid Masterbatch:

Process Aid Masterbatch serves as a vital additive in polymer processing, designed to optimize various aspects of the manufacturing process. Unlike traditional additives that modify the properties of the polymer itself, Process Aid Masterbatch focuses on improving the overall processing characteristics. It acts as a facilitator, enhancing the flow properties, reducing friction, and promoting uniformity during the processing stages.

The Significance of Process Aid Masterbatch:

The incorporation of Process Aid Masterbatch brings a multitude of advantages to polymer processing. Firstly, it aids in the effortless flow of polymer materials, reducing the likelihood of melt fracture and enhancing the surface finish of the end product. Secondly, it contributes to the overall efficiency of processing machinery by minimizing energy consumption and improving throughput. Ehda Polymer Co recognizes the critical role of Process Aid Masterbatch and has emerged as a frontrunner in its production.

Production Process of Process Aid Masterbatch:

The production process of Process Aid Masterbatch at Ehda Polymer Co is a sophisticated and systematic procedure aimed at achieving optimal results. The company’s commitment to excellence is reflected in each stage of production:

-

Raw Material Selection:

The journey begins with the careful selection of high-quality polymers that form the base of the masterbatch. Ehda Polymer Co places emphasis on understanding the specific processing requirements and characteristics of the targeted polymers.

-

Addition of Process Aid:

The key component of Process Aid Masterbatch is the addition of processing aids. These aids are meticulously chosen and blended with the base polymer to create a masterbatch that enhances the processing characteristics. Ehda Polymer Co leverages advanced blending techniques to ensure a homogeneous mixture.

-

Compounding and Homogenization:

The compounded mixture undergoes a thorough compounding process, subjecting it to controlled temperature and pressure conditions. This phase is crucial for achieving homogeneity within the masterbatch, ensuring that the processing aids are evenly distributed, and their effectiveness is optimized.

-

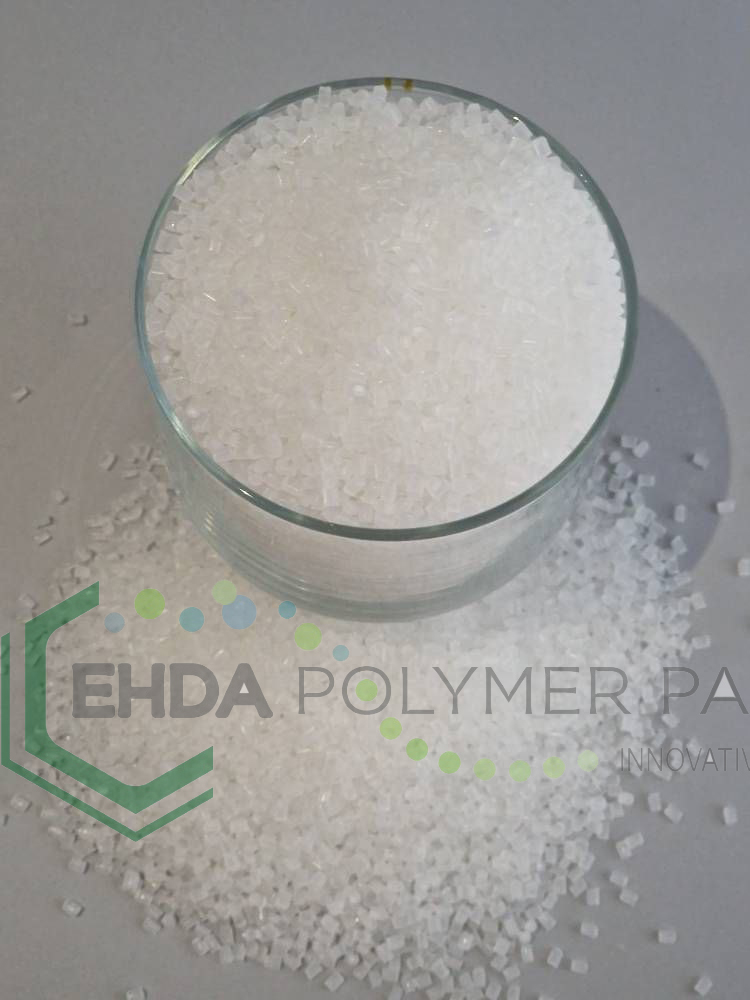

Pelletization:

The homogenized mixture is then pelletized, transforming it into uniform pellets. This form facilitates easy handling and incorporation into polymer processing machines. The consistency achieved during pelletization is vital for ensuring predictable and reliable performance.

-

Quality Control Measures:

Quality control at Ehda Polymer Co is a non-negotiable aspect of the production process. Rigorous testing measures are implemented to verify the effectiveness of processing aids, homogeneity of the masterbatch, and overall product consistency. This commitment to quality ensures that the Process Aid Masterbatch meets or exceeds industry standards.

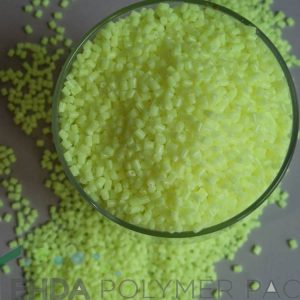

A Spectrum of Process Aid Masterbatch:

Ehda Polymer Co takes pride in its ability to produce a diverse range of Process Aid Masterbatch, tailored to meet the unique requirements of various polymer processing applications. Whether it’s improving extrusion processes, injection molding, or blow molding, Ehda Polymer Co offers customized solutions to enhance efficiency across the polymer processing spectrum.

Applications and Benefits:

Process Aid Masterbatch, produced by Ehda Polymer Co, finds applications across a multitude of industries. In the packaging sector, it optimizes the extrusion process, resulting in smoother films and enhanced packaging quality. In injection molding, it improves mold filling and reduces cycle times, leading to increased productivity. The benefits extend to blow molding processes, where the masterbatch enhances parison formation and overall product aesthetics.

Future Trends in Polymer Processing:

As the polymer industry continues to evolve, the demand for specialized additives like Process Aid Masterbatch is expected to grow. Ehda Polymer Co, with its commitment to innovation, is well-positioned to anticipate and address emerging trends. The future may see advancements in sustainable processing aids, aligning with the industry’s increasing focus on eco-friendly solutions.

In conclusion, Procces Aid Masterbatch stands as a pivotal player in optimizing polymer processing, streamlining production, and enhancing the quality of end products. Ehda Polymer Co’s dedication to the production of high-quality Procces Aid Masterbatch cements its status as a leader in the polymer industry. As industries continue to seek efficiency and excellence in polymer processing, the role of innovative companies like Ehda Polymer Co becomes increasingly indispensable. The Procces Aid Masterbatch produced by Ehda Polymer Co not only reflects their commitment to current industry demands but also positions them as trailblazers shaping the future of polymer processing.

Ehda Polymer Co’s Competitive Edge:

Ehda Polymer Co’s position as a prominent producer of Procces Aid Masterbatch is fortified by its commitment to providing value beyond the product itself. The company’s investment in research and development not only ensures high-quality masterbatch but also positions it competitively in terms of innovation and versatility.

Customization and Technical Support:

Ehda Polymer Co distinguishes itself by offering customization options based on specific customer needs. The company provides technical support to clients, assisting them in selecting the most suitable formulations for their polymer processing applications. This personalized approach enhances customer satisfaction and loyalty.

* **Sustainability Initiatives:**

As the industry places an increasing emphasis on sustainability, Ehda Polymer Co is committed to incorporating eco-friendly practices into its production processes. This commitment aligns with the growing demand for sustainable solutions, providing the company with a competitive edge in the global market.

Global Trends and Challenges:

Looking ahead, the Process Aid Masterbatch market is poised for continued growth on a global scale. The integration of polymer materials into diverse industries is expected to persist, driving the demand for specialized additives. However, challenges such as fluctuating raw material prices, evolving regulatory landscapes, and the need for constant innovation to meet diverse industry requirements may shape the future trajectory of the Process Aid Masterbatch market.

*Global Price Levels of Process Aid Masterbatch:

The global price levels of Procces Aid Masterbatch are influenced by the interplay of supply and demand dynamics on a worldwide scale. As industries across continents increasingly recognize the importance of optimized polymer processing, the demand for high-quality Procces Aid Masterbatch rises. This global demand creates a competitive landscape where producers, including Ehda Polymer Co, play a crucial role in meeting market needs. Currently its dealing depend on its quality: 1200 – 2200 $ per ton

Supply and Demand Balance:

The delicate balance between supply and demand has a direct impact on the pricing of Process Aid Masterbatch. The global market dynamics, influenced by factors such as industry trends, technological advancements, and economic conditions, contribute to the determination of price levels.

Raw Material Costs:

Fluctuations in the costs of raw materials, such as polymers and processing aids, can have a cascading effect on the pricing of Process Aid Masterbatch. Ehda Polymer Co’s ability to manage and optimize raw material costs positions it strategically in maintaining competitive pricing.

Technological Advancements:

Ongoing technological advancements in polymer processing and additive manufacturing can influence global price levels. Producers that stay at the forefront of innovation and leverage cutting-edge technologies may command premium prices for their advanced Process Aid Masterbatch formulations.

**Conclusion:**

In conclusion, Ehda Polymer Co’s role in the production of Process Aid Masterbatch extends beyond meeting current market demands; it reflects a forward-thinking approach that anticipates and shapes future industry trends. As the global demand for efficient polymer processing solutions continues to rise, the collaboration between producers like Ehda Polymer Co and their clients becomes instrumental in driving innovation and ensuring the continued success of the Process Aid Masterbatch market. The company’s commitment to quality, sustainability, and technological innovation positions it as a leader not only in the production of Process Aid Masterbatch but also in shaping the future landscape of the polymer industry on a global scale.