Anti Block Masterbatch

Introduction:

In the ever-evolving landscape of polymer materials, the demand for specialized additives continues to rise. One such innovation that has gained prominence is the Anti Block Masterbatch, a crucial component in the polymer industry. This article delves into the production process of Anti Block Masterbatch, shedding light on its significance, and highlighting Ehda Polymer Co as a notable producer in this dynamic field.

Understanding Anti Block Masterbatch:

Anti Block Masterbatch is a vital additive designed to minimize the adhesion between polymer surfaces, preventing them from sticking together. This phenomenon, known as blocking, can occur during the production, processing, or application of polymer materials. The masterbatch acts as a lubricating agent, enhancing the slip properties of the polymers and facilitating their smooth separation.

The Significance of Anti Block Masterbatch:

The incorporation of Anti Block Masterbatch in polymer processing offers several advantages. Firstly, it improves the handling and processing of polymer films, sheets, and other products by reducing surface friction. This not only enhances the overall efficiency of manufacturing processes but also contributes to the quality of the end product. Additionally, Anti Block Masterbatch aids in preventing film blocking during storage and transportation, ensuring the product’s integrity.

Production Process of Anti Block Masterbatch:

The production of Anti Block Masterbatch involves a meticulous process to achieve the desired properties and effectiveness. Ehda Polymer Co, a leading player in the polymer industry, has perfected this process, ensuring the delivery of high-quality masterbatches.

-

Selection of Base Polymers:

The production begins with the careful selection of base polymers. Ehda Polymer Co considers the specific requirements of the end application and the polymer matrix to create a masterbatch that complements and enhances the performance of the base polymer.

-

Addition of Slip Agents:

The key to Anti Block Masterbatch lies in the incorporation of slip agents. These additives, often composed of specialized chemicals, are blended with the base polymer in precise quantities. Ehda Polymer Co employs state-of-the-art technology to ensure uniform dispersion of slip agents, a crucial factor in achieving optimal anti-blocking properties.

-

Compounding Process:

The compounded mixture undergoes a compounding process, where it is subjected to controlled temperature and pressure conditions. This phase is crucial for achieving homogeneity within the masterbatch, ensuring that the slip agents are evenly distributed throughout the polymer matrix.

-

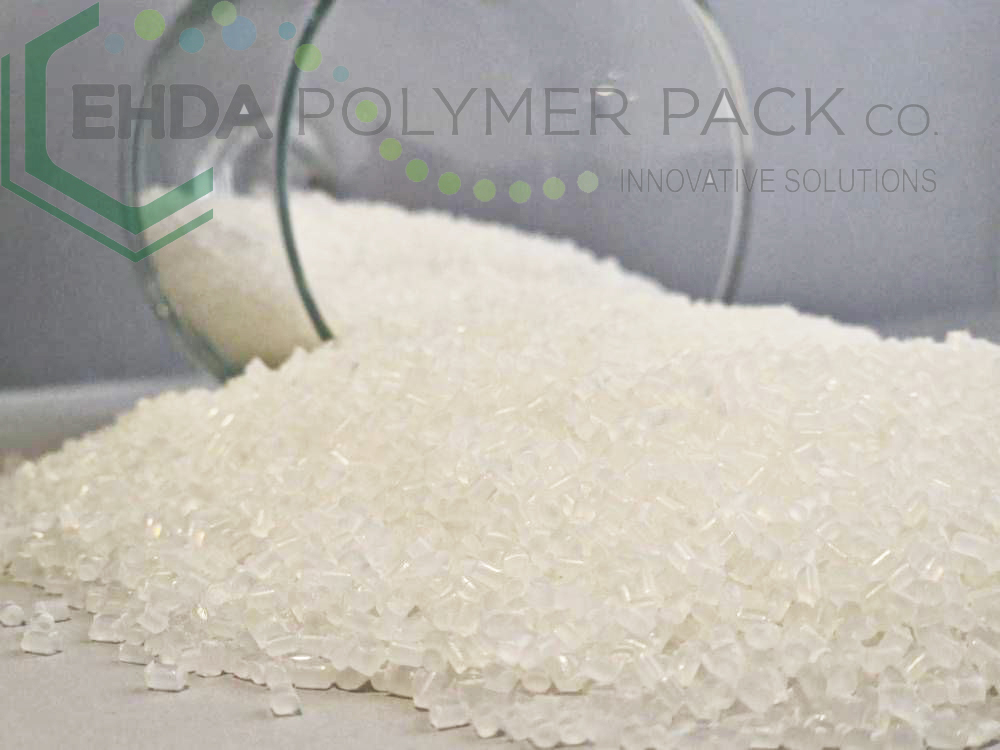

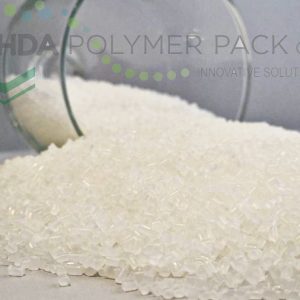

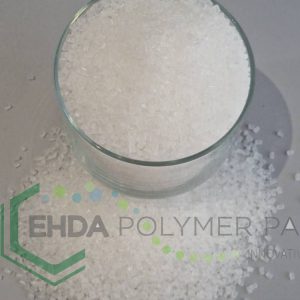

Pelletization:

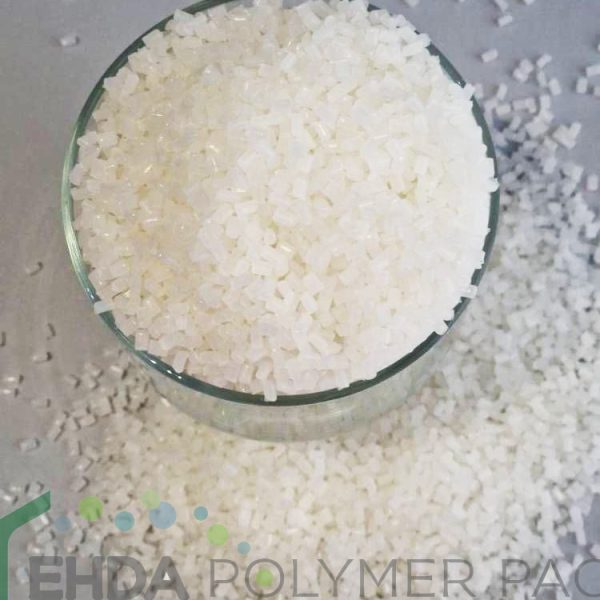

The homogenized mixture is then pelletized, transforming it into small, uniform pellets. This not only facilitates easy handling but also ensures consistent performance during the subsequent processing stages.

-

Quality Control:

Ehda Polymer Co places a strong emphasis on quality control at every stage of the production process. Rigorous testing measures are implemented to verify the anti-blocking efficacy, dispersion of additives, and overall consistency of the masterbatch.

Ehda Polymer Co has emerged as a key player in the production of Anti Block Masterbatch, setting industry standards through its commitment to excellence. The company’s investment in research and development, coupled with cutting-edge technology, positions it at the forefront of innovation in the polymer industry.

Innovation Beyond Anti Block Masterbatch:

Ehda Polymer Co’s commitment to innovation extends beyond Anti Block Masterbatch. The company continually explores new formulations, ensuring that its products meet the evolving needs of the industry. With a focus on sustainability and performance, Ehda Polymer Co remains dedicated to pushing the boundaries of polymer technology.

Conclusion:

In conclusion, Anti Block Masterbatch plays a pivotal role in enhancing the performance of polymer materials, preventing blocking issues and improving overall product quality. Ehda Polymer Co’s dedication to excellence in the production process ensures that its masterbatch meets the highest industry standards. As we look towards the future of polymer technology, the role of innovative companies like Ehda Polymer Co becomes increasingly crucial in driving advancements and meeting the diverse demands of the market.

The Market Dynamics of Anti Block Masterbatch:

The market for Anti Block Masterbatch has experienced significant growth in recent years, driven by the expanding applications of polymer materials across various industries. As manufacturers seek to improve the quality and functionality of their products, the demand for specialized additives like Anti Block Masterbatch continues to rise.

Industry Applications:

Anti Block Masterbatch finds applications in a wide range of industries, including packaging, agriculture, automotive, and construction. In the packaging industry, for instance, the masterbatch is extensively used in the production of films, sheets, and containers to prevent blocking during storage and transportation. In agriculture, it contributes to the efficiency of agricultural films, ensuring that they can be easily unrolled without sticking together. The automotive and construction sectors also benefit from the improved processing and performance of polymer materials containing Anti Block Masterbatch.

Global Reach:

The market for Anti Block Masterbatch is not confined to a specific region; it has a global reach. As industries across the world increasingly adopt polymer materials in their processes, the demand for high-quality additives rises proportionally. This global demand has led to a competitive landscape with various companies, including Ehda Polymer Co, playing a crucial role in meeting the market’s needs.

Pricing Considerations:

The pricing of Anti Block Masterbatch is influenced by several factors, reflecting the complexity of its production process and the specific requirements of end-users. Key factors that contribute to the pricing dynamics include:

-

Composition and Formulation:

The precise composition and formulation of Anti Block Masterbatch can vary based on the polymer matrix it is intended to enhance. Different applications may require specific formulations, and the inclusion of certain additives can affect the overall cost of production.

-

Quality and Purity:

The quality and purity of Anti Block Masterbatch significantly impact its pricing. Manufacturers, such as Ehda Polymer Co, that prioritize quality control measures and adhere to stringent standards often position their products at a premium.

-

Market Competition:

The level of competition within the market plays a role in determining the pricing strategy of Anti Block Masterbatch. Companies that offer unique formulations, consistent quality, and reliable performance may command higher prices in the market.

-

Packaging and Handling:

The form in which Anti Block Masterbatch is supplied, whether in bulk, bags, or other packaging options, can influence its pricing. Additionally, considerations for ease of handling and transportation may contribute to variations in pricing.

Ehda Polymer Co’s Competitive Edge:

Ehda Polymer Co’s position as a producer of Anti Block Masterbatch is strengthened by its commitment to providing value beyond the product itself. The company’s investment in research and development not only ensures high-quality masterbatch but also positions it competitively in terms of innovation and versatility.

Customization and Technical Support:

Ehda Polymer Co distinguishes itself by offering customization options based on specific customer needs. The company provides technical support to clients, assisting them in selecting the most suitable formulations for their applications. This personalized approach enhances customer satisfaction and loyalty.

Sustainability Initiatives:

As the industry places an increasing emphasis on sustainability, Ehda Polymer Co is committed to incorporating eco-friendly practices into its production processes. This commitment aligns with the growing demand for sustainable solutions, providing the company with a competitive edge in the market.

Future Trends and Challenges:

Looking ahead, the market for Anti Block Masterbatch is poised for continued growth. As industries evolve and demand for high-performance polymer materials increases, the need for effective additives will rise correspondingly. However, challenges such as fluctuating raw material prices, regulatory considerations, and the need for constant innovation to meet diverse industry requirements may shape the future landscape of the Anti Block Masterbatch market.

In conclusion, Ehda Polymer Co‘s role in the production of Anti Block Masterbatch reflects not only a commitment to meeting current market demands but also a forward-thinking approach that anticipates future industry trends. As technology advances and industries continue to embrace polymer materials, the collaboration between producers like Ehda Polymer Co and their clients becomes instrumental in driving innovation and ensuring the continued success of the Anti Block Masterbatch market.

Other Products:

In addition to our core offerings of white masterbatch, slip additives, optical brighteners, anti-block, and processing aid additives, EHDA Polymer Pack Co. takes pride in a diverse product portfolio that includes specialty solutions such as slipper masterbatch, filler masterbatch, and compounds designed specifically for blown film and pipe applications. Our slipper masterbatch ensures excellent slip properties, enhancing the processing efficiency of various polymers. Filler masterbatch, on the other hand, provides cost-effective solutions without compromising on quality, imparting desirable properties to the final product. Furthermore, our compounds tailored for blown film and pipe applications are formulated to meet the unique performance requirements of these industries, delivering superior quality and consistency. These specialized products showcase our commitment to innovation, providing comprehensive solutions that cater to the specific needs of our clients across a wide range of applications.”

Contact

Linkedin