Recycling collation shrink film

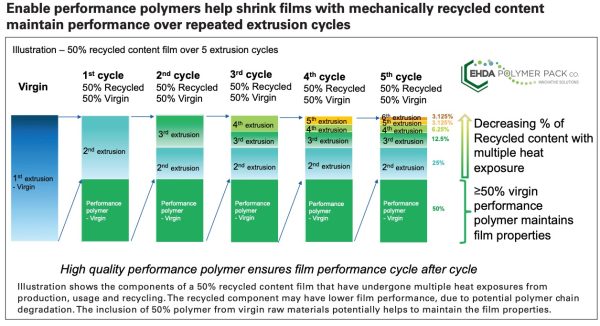

Every occurrence of elevated temperature and shearing speed can induce degradation of polymer chains and the deterioration of mechanical functionality.

If one were to consistently gather, organize, and upcycle the identical contraction wrap, it would imply that the same recycling stream would be subjected to these temperature increases repeatedly, exacerbating the situation.

Certain contraction wrap materials may no longer merit classification as disposable plastics, assert three enterprises that have effectively devised a resolution for mechanically recycling contraction wraps comprising 50% recycled material content.

Certain contraction wrap materials may no longer necessitate classification as disposable plastics, thanks to an inventive solution that may facilitate their mechanical recycling multiple times without jeopardizing their efficacy.

The resolution, enabling contraction wrap materials containing 50% recycled content, has passed a “proof of concept” phase, signifying that the materials met required performance standards after three months of examination in a three-way partnership involving materials firm ExxonMobil, Malaysian processor Thong Guan Industries Berhad, and Malaysian testing facility, Newton Research and Development Centre.

Recycling collation shrink film

“Wrap films

play a vital role in preserving food and beverages, but are commonly discarded post-use. This is primarily due to inadequate collection and sorting facilities and the perceived processing obstacles posed by recycled plastics,” reveals Chan Kwee Lin, ExxonMobil’s Asia Pacific Advanced Recycling and Sustainability Market Manager.

“ExxonMobil is devising solutions to enhance the recyclability of these essential films. We aspire to alter the industry’s mindset, motivating more enterprises to extract value and prolong the usage of wrap films not just once, but recurrently, thereby potentially mitigating a source of plastic waste globally,” he adds.

The tripartite collaboration was initiated by Thong Guan, a prominent packaging film manufacturer in Malaysia and Southeast Asia. Its senior general manager, David Ang, elucidates the project’s inception: “The chief value we recognize in utilizing recycled wrap films is the potential reduction in materials directed to landfills. Concurrently with the potential recyclability of polyethylene (PE) wrap film, it presents a splendid opportunity to support our objective of closing the plastic loop. Leveraging the outcomes of this project, our primary objective is to demonstrate that we can uphold quality performance in wrap films by incorporating post-consumer recycled (PCR) content. This, in turn, bolsters our company’s endeavor to advocate plastic circularity.”

Recycling collation shrink film

Recycling collation shrink film

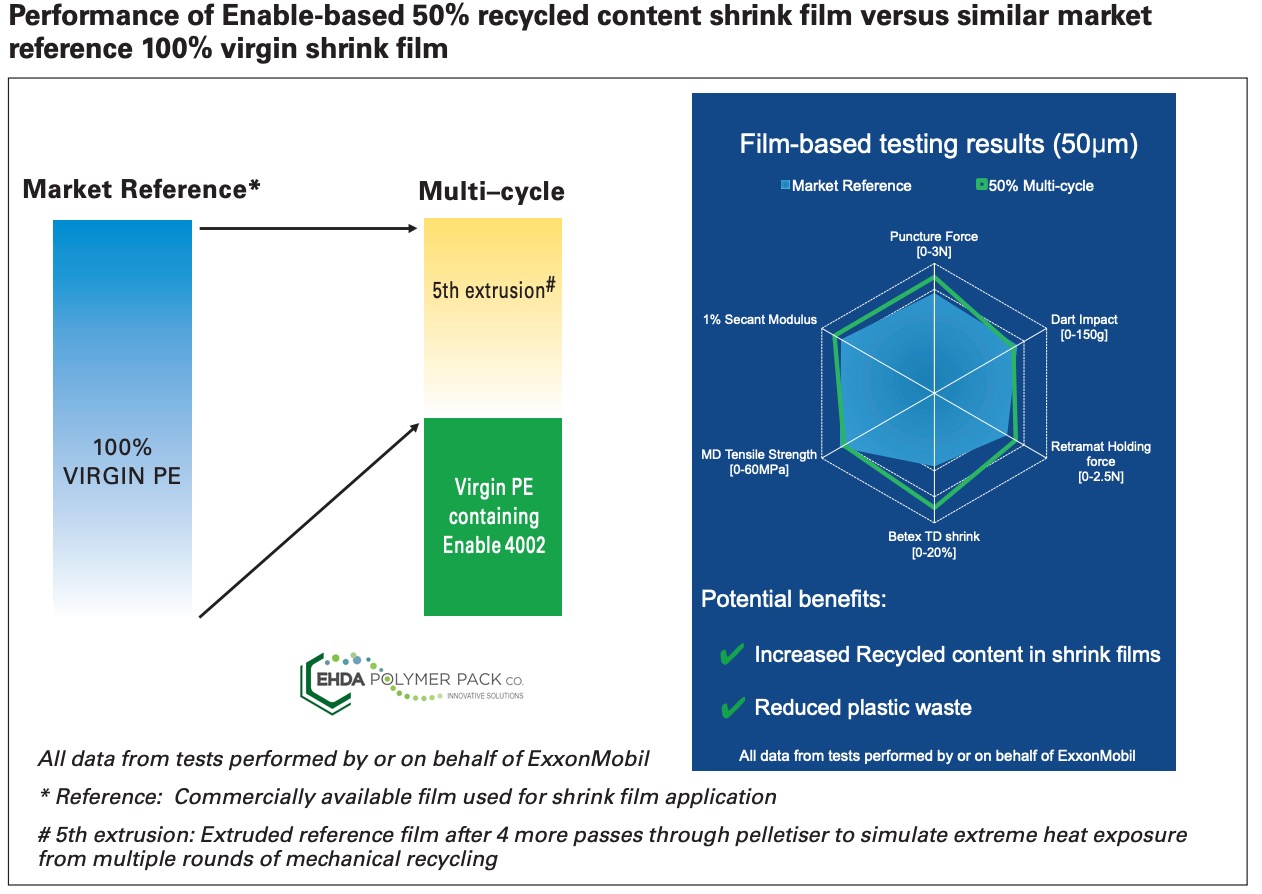

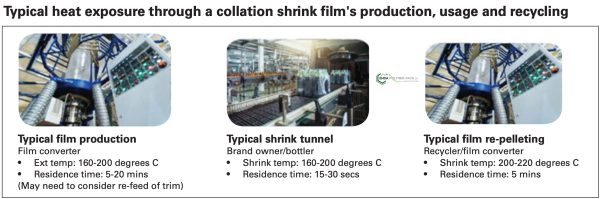

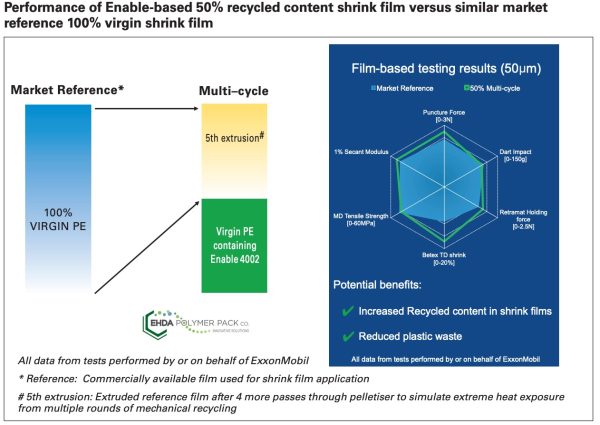

However, the integration of recycled content (particularly PCR) in contraction wrap films can pose challenges. When manufacturing contraction-wrap films from mechanically recycled PE, there are three stages where the raw material is exposed to heat: film production, shrink tunnel operations, and film repelleting for recycling.

Alleviating the weakening of film strength

Thong Guan collaborated with ExxonMobil to devise a solution to mitigate the potential decline in mechanical strength resulting from the inclusion of recycled content. They enlisted further assistance in testing the solution from Newton Research and Development Centre, a preeminent research institute in Malaysia specializing in packaging solutions for palletized loads.

ExxonMobil proposed a solution incorporating Enable 4002 performance polymers. “When utilized alongside recycled PE streams, Enable polymers can aid in sustaining the requisite mechanical and processing capabilities to reduce the performance variability typically linked with mechanically recycled PE film. This approach yields a final product

Market for recycled wrap films in beverage sector

Is there a market for recycled wrap films? Ang affirms, “Recycled wrap films are highly sought after in the beverage industry. We distribute some domestically and export to countries like Australia and New Zealand.”

Ang also divulged that recycled wrap films may entail higher production costs than virgin films, yet there remains demand from enterprises with sustainability objectives and commitments, potentially benefiting from tax advantages depending on their market.

Recycling collation shrink film

“Our clients could potentially economize on plastic packaging expenses by fulfilling the requisites of various plastic packaging tax schemes like the one enforced in the UK, where companies employing plastic packaging with less than 30% recycled content are mandated to pay a tax of £200 per tonne of plastics.”

Recycling collation shrink film

For now, perhaps only one obstacle impedes the increased production of wrap films with recycled content.

Ang jests,

“The reception to our recycled wrap film is outstanding as more enterprises are pursuing their sustainability goals and commitments. However, the commercialization of wrap films containing recycled content largely hinges on the availability of high-quality recycled content.

Making superior recycled content widely accessible will necessitate investment and close collaboration throughout the entire packaging value chain.”

Ehda polymer, a novel material in the realm of polymer science, has garnered significant attention for its unique properties and diverse applications. Developed through advanced research and innovative synthesis techniques, Ehda polymer exhibits remarkable versatility, offering solutions across various industries ranging from healthcare to electronics. Its exceptional strength, flexibility, and chemical resistance make it ideal for use in biomedical devices, electronic components, and advanced packaging materials. Moreover, Ehda polymer’s environmentally friendly composition and recyclability contribute to its growing popularity as a sustainable alternative in the manufacturing landscape. As researchers continue to explore its potential, Ehda polymer promises to revolutionize materials science and drive innovation in numerous sectors.