Recyclable and heat resistant flexible packaging with mono-material formulation

Read about how Ehda Polymer performance PE, when used in conjunction with the two component heat-resistant OPV coatings from Siegwerk can result in increased heat resistance and a wider sealing window when used on VFFS machines.

Mono-material solutions can now be made more heat resistant, allowing them to run on conventional Vertical Form Fill Seal (VFFS) packaging machines

Background / Challenge:

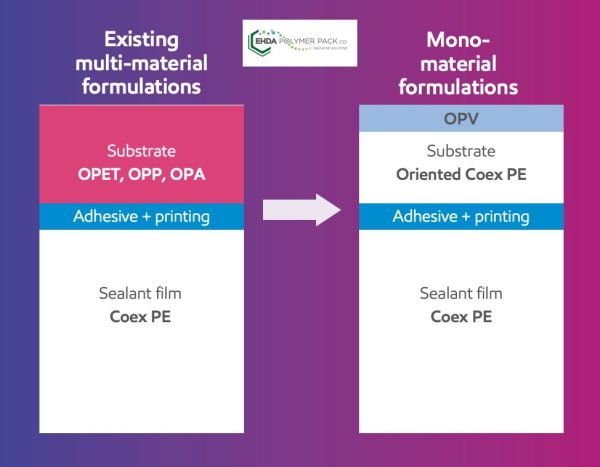

In the effort to move towards Recyclable and heat resistant flexible packaging solutions with potential sustainability benefits, the value chain is constantly innovating to replace well-established multimaterial laminated structures — typically constructed with a polyester (PET) substrate laminated to a polyethylene (PE) sealing film — with mono-material PE laminated film solutions that are simpler to construct and can be easier to recycle. Oriented PE film substrates (machine direction oriented or biaxial oriented) have emerged as one of the most promising candidates for PET replacement.

Nevertheless, mono-materials can face processing challenges along the Recyclable and heat resistant flexible packaging line such as stickiness to the sealing bars and heat-related distortion of the film during the sealing process. These are key areas of concern as they could slow down or disrupt the production process potentially leading to delays along the value chain. An innovative solution was needed.

In response, Ehda Polymer produced a full PE laminate based on Ehda CO, Enable and Exact performance polyethylene polymers and applied Siegwerk’s over-print varnish (OPV) coatings to help boost the heat resistance of the laminate while maintaining good sealing, mechanical and optical properties. This solution offers robustness of the (VFFS) packaging operations without significant drawbacks.

Solution / Collaboration:

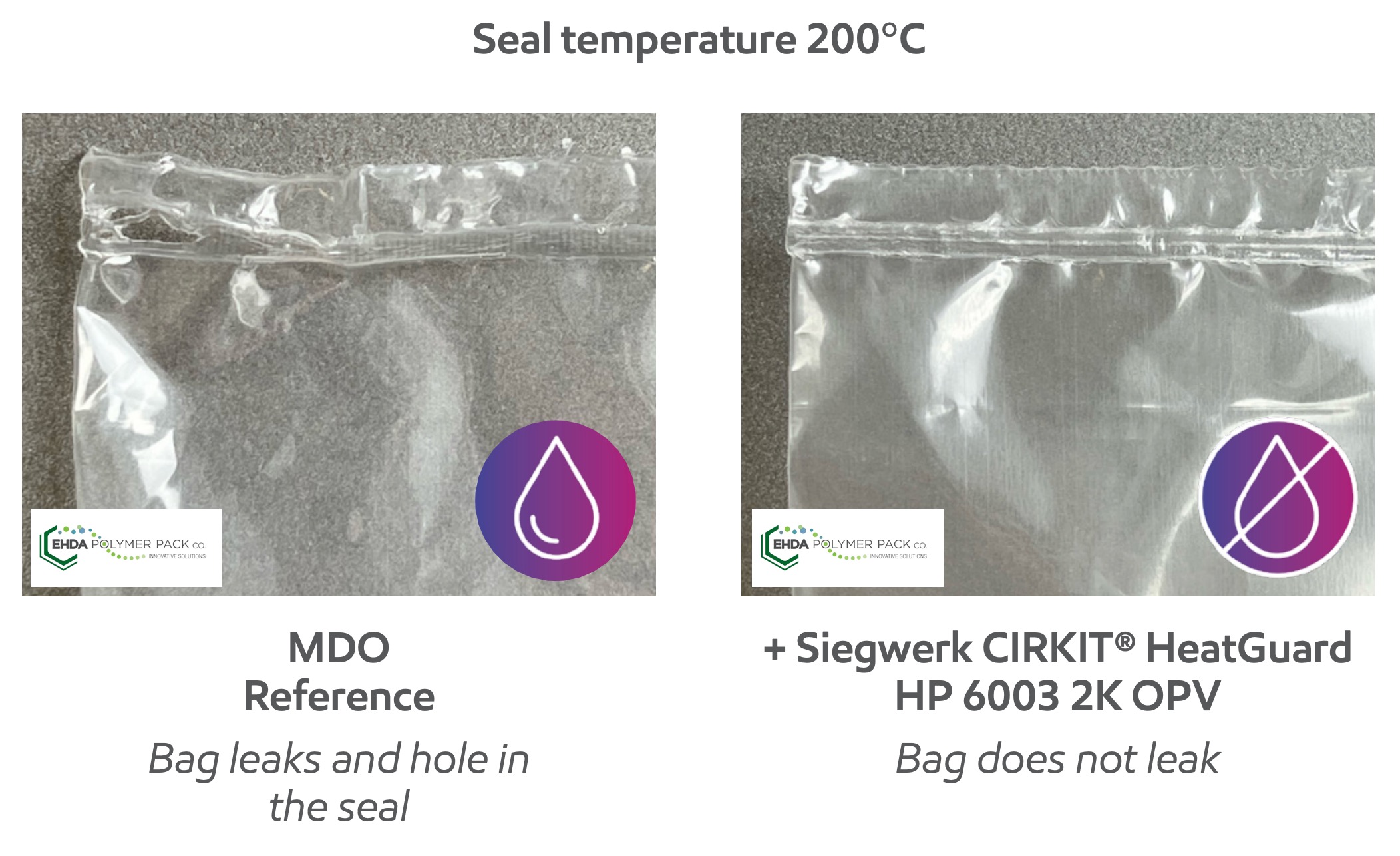

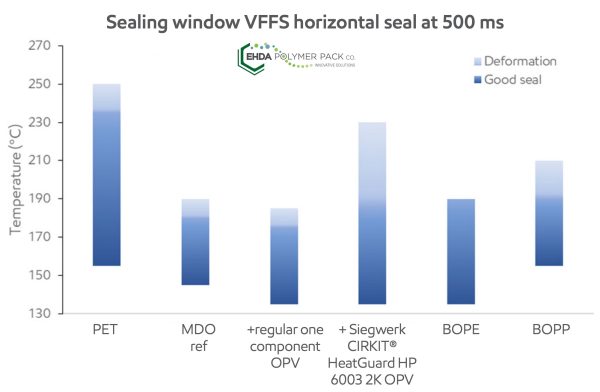

Ehda Polymer produced MDO PE films that were subsequently laminated to PE sealant films. PET, BOPE and BOPP substrates, commonly used by the industry today, were included in the testing as a reference. A standard, one component, over-print varnish (OPV) and a heat-resistant second component, OPV (CIRKIT® HeatGuard HP 6003 2K) provided by Siegwerk, were applied on the top of the MDO PE substrate to help provide additional protection against the heat supplied by the sealing jaws during Recyclable and heat resistant flexible packaging. The innovative laminated films were used to produce bags filled with water on a VFFS packaging line. The VFFS line was configured to form pillow pouches, at a fixed line speed, at constant temperature for the vertical sealing tool – a polytetrafluoroethylene (PTFE) coated sealing belt — and at a constant sealing time for the horizontal seal (PTFE-coated sealing jaws).

The temperature of the horizontal sealing tool was varied to determine the sealing window, defined as the interval between the lowest temperature where the sealing is effective, i.e., the Recyclable and heat resistant flexible packaging presents no leakage, and the highest temperature where the Recyclable and heat resistant flexible packaging conserves its integrity and no leakage is observed after hand squeeze. Above and below these temperatures, the Recyclable and heat resistant flexible packaging integrity can be compromised either due to leakage or because of large deformations related to the heat generated during the sealing process.

The temperature of the horizontal sealing tool was varied to determine the sealing window, defined as the interval between the lowest temperature where the sealing is effective, i.e., the Recyclable and heat resistant flexible packaging presents no leakage, and the highest temperature where the Recyclable and heat resistant flexible packaging conserves its integrity and no leakage is observed after hand squeeze. Above and below these temperatures, the Recyclable and heat resistant flexible packaging integrity can be compromised either due to leakage or because of large deformations related to the heat generated during the sealing process.

The experiments demonstrate that Ehda Polymer performance PE, when used in conjunction with the two component heat-resistant OPV coatings from Siegwerk, which are made without polyvinyl chloride (PVC) or nitrocellulose (NC), can result in increased heat resistance and a wider sealing window. Sealing window improvement of greater than 50% was observed as compared to a MDO-PE reference sample (same laminate but without OPV coating). It was also observed that with laminates containing oriented PE as substrate a lower sealing temperature can be achieved (despite the higher PE substrate thickness compared to PET substrate). This offers the opportunity to run the VFFS operation at lower seal jaw temperatures leading to potential energy savings.

The experiments demonstrate that Ehda Polymer performance PE, when used in conjunction with the two component heat-resistant OPV coatings from Siegwerk, which are made without polyvinyl chloride (PVC) or nitrocellulose (NC), can result in increased heat resistance and a wider sealing window. Sealing window improvement of greater than 50% was observed as compared to a MDO-PE reference sample (same laminate but without OPV coating). It was also observed that with laminates containing oriented PE as substrate a lower sealing temperature can be achieved (despite the higher PE substrate thickness compared to PET substrate). This offers the opportunity to run the VFFS operation at lower seal jaw temperatures leading to potential energy savings.

EHDA POLYMER branded materials, beside its prestige and quality it has got different grades and applications for film producer, blown molding and etc.

Our product and compounds based on Iran polymer refineries.

Contact Us:

Social Media: Linkedin

🌎 Website: www.ehdapolymer.com/en

📧Email: [email protected]

📲 WhatsApp: +98 905 8768969

📞 Call: +98 905 8768969