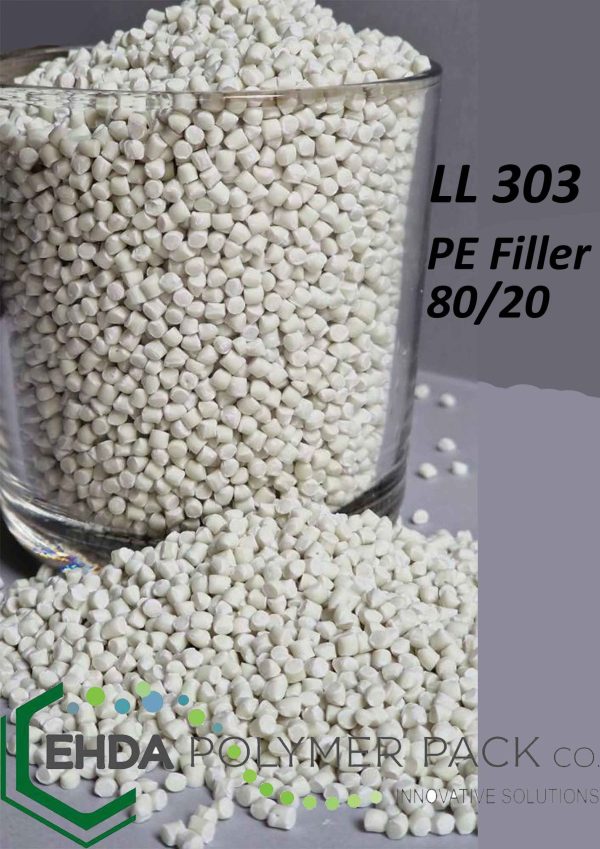

Ehda reliable Filler Masterbatch

Ehda Filler Masterbatch is a various kinds of PE and PP based calcium carbonate fillers compounds.

-

Filler Masterbatch CACO3 FILLED COMPOUND WITH PE CARRIER

Industries: Extrusion, HDPE & LDPE Film, PP Raffia, Pipe, Blow Molding, Injection

-

Filler Masterbatch CACO3 FILLED COMPOUND WITH PP CARRIER

Industries: Extrusion, PP Raffia, Pipe, Injection, Thermoform

Depending on the application, these compounds can add special characteristics to the final products. Some of these are Increasing of stiffness, increasing of the film production output better cooling of the bubble, reduction of the energy usage during the production process, and great distribution in the polymer base of the product.

Ehda polymer’s filler compounds can help reduce the final product’s cost, increase production rate, improve the printing process, result in better opening of the film layers. Also adding correct amount of filler compounds improves the some of the mechanical properties such as impact resistance and better bubble stability.

Filler Masterbatch

The Role of Filler Masterbatch in Plastic Industries:

Understanding the Usage of CaCO3 and Alternative Bases

Introduction

Filler masterbatch plays a pivotal role in plastic industries, enhancing the properties of plastic materials. Among the various fillers, Calcium Carbonate (CaCO3) is a widely utilized and cost-effective choice. Additionally, other bases apart from CaCO3 contribute to the production of filler masterbatch, each offering distinct benefits. Understanding the manufacturing process, application, and diverse uses of filler masterbatch aids in comprehending its significance in plastic production.

Usage of CaCO3 in Filler Masterbatch

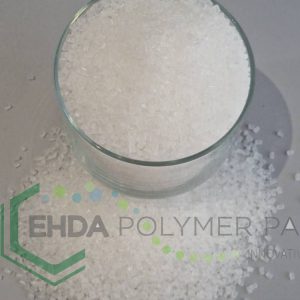

Calcium Carbonate (CaCO3) serves as an ideal filler in the plastic industry due to its affordability, availability, and ability to enhance various plastic properties. It is primarily used in the production of filler masterbatch. The addition of CaCO3 filler masterbatch in plastics can improve stiffness, impact resistance, and reduce material costs without compromising the quality of the end product. The process involves blending CaCO3 with a carrier resin, enabling easier incorporation into the plastic during the manufacturing process.

Filler Masterbatch

Production Process of Filler Masterbatch with CaCO3

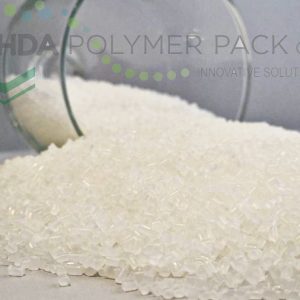

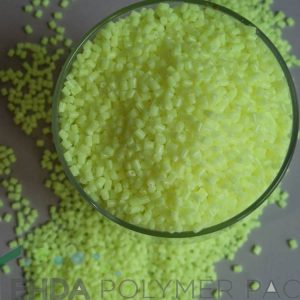

The manufacturing process of Filler Masterbatch involves several steps. Initially, the CaCO3 is compounded or mixed with a carrier resin, which acts as a binder. This mixture undergoes extrusion to form small pellets or granules. These pellets are subsequently cooled and cut into the desired size, resulting in the final filler masterbatch product ready for incorporation into the plastic during the production phase.

Filler Masterbatch with Alternative Bases

Apart from CaCO3, various other bases contribute to filler masterbatch production. Talc, a naturally occurring mineral, serves as a filler and reinforcement agent in plastics, enhancing stiffness and heat resistance. Additionally, other bases like glass beads, silica, and barium sulfate offer diverse properties such as improved impact resistance, transparency, and electrical insulation, depending on the specific application requirements.

Different Usages of Filler Masterbatch

Filler Masterbatch finds extensive usage across multiple industries due to its versatile properties. In the automotive sector, it reinforces plastic parts, improving mechanical strength and reducing weight, contributing to fuel efficiency. In packaging, it enhances the durability and printability of plastic films and containers. Construction materials benefit from filler masterbatch by improving weatherability, thermal stability, and reducing costs.

Moreover, Filler Masterbatch aids in electrical applications, where it provides insulation, flame retardancy, and mechanical properties essential for electrical components. The appliance industry benefits from its ability to improve aesthetics, durability, and cost-effectiveness in producing various household items.

Conclusion

Filler Masterbatch, particularly those containing CaCO3 and alternative bases, significantly impacts the plastic industry by improving mechanical, thermal, and cost-related properties of plastic materials. The production process involves compounding the filler with a carrier resin to create masterbatch pellets, ensuring easy integration into plastic manufacturing. The usage of Filler Masterbatch extends across numerous sectors, playing a vital role in enhancing various product properties while optimizing costs. Understanding the significance and diversity of Filler Masterbatch is crucial for industries seeking to improve their plastic materials’ performance and economics.

Purchasing Filler Masterbatch:

For information regarding prices and purchasing terms for Filler Masterbatch, please contact our experts.

For exporting Filler Masterbatch, get in touch with our professionals.

Покупка белого мастербатча:

Для получения информации о ценах и условиях покупки белого мастербатча, пожалуйста, свяжитесь с нашими экспертами.

WA: +989058768969

Для экспорта белого мастербатча, обратитесь к нашим специалистам.